Products

SQRTM & RTM TOOLING

Our Development and Tooling engineers are skilled in developing composite manufacturing processes and designing closed mold, metallic tooling that produces highly integrated composite structures with unsurpassed quality.

Tooling Features & Benefits

- Part forming cavities are designed to a target composite cured ply thickness providing better control of composite mechanical properties.

- Tool registration features locate and control insert and preform positioning resulting in improved dimensional control and repeatability of the composite structure.

- Closed mold tooling allows direct control of the hydrostatic pressure within the mold during the composite fabrication cycle resulting in superior part quality.

- Improved thermal uniformity is realized allowing increased thermal ramp rates reducing cycle times.

- The composite manufacturing process and tooling allow scale-up from initial process development trials and sub-elements to full-scale structures with minimal process modifications.

- Tool handling fixtures are designed and fabricated to aid in tool assembly/disassembly providing improved cycle times and tool longevity.

- Tools are designed to integrate seamlessly with Radius Engineering Workcell and Injection systems.

- Single and Multi-cavity tool utilization to optimize equipment usage and reduce recurring costs.

Highlighted Projects

Design & Build

Radius Engineering designs and builds composite manufacturing workcells to the precise specifications required by our customers for successful composite manufacturing. We provide ongoing training, service and technical support that facilitates continuous process improvement and a reliable supply of spare parts.

Press Purpose and Features

- Provide automated production equipment for OOA manufacturers with precise control over time, temperature, and pressure.

- Contain closed mold tooling during high-pressure injection and cure.

- Apply Clamping Pressure to the tool.

- Maintain Tool Shape - under high internal pressures (150 psi).

- Apply Even & Efficient Heating to the Tool.

- Cool the Tool after cure.

Workcells integrate well with Radius injectors and tooling. Radius PressWareTM control software provides consistent control of the entire process.

Pneumatic Presses

Press Features

Our engineers build presses designed specifically for RTM and SQRTM composite manufacturing. Our unique pneumatic press design has distinct advantages for manufacturers who require tight process control and high volume production efficiency.

Standard Features:

- Up to 300 PSI Tool Clamping Pressure

- Up to 800° F (425° C)

- Tool Sizes up to 300“ x 60”

- Precise Temperature Control

- Electric Heating Elements

- Integrated Thermocouple Feedback

- Multi-Zone Temperature Controls

- Even clamping pressure

- Lower Bolster “Floats” on bed of pneumatic hoses providing evenly distributed forces on part tools

- Eliminates possibility of equipment damage from binding actuators

- Compare: Press with Bolsters vs. Self Clamping Tool

- Standard maximum platen deflection of .005”

- Clean process with minimal fluids and lubricants

- Gentle tool closing pressure

- Quiet – no hydraulics

- Integrate perfectly with Radius Injectors

Optional Features:

- Actuated Daylight Adjustment

- Controlled Tool Cooling

- Vacuum System

- Automated Tool Handling Equipment

- Automated Tool Loading/Unloading

- Custom Safety Systems & Guarding

- CE Certification

- Clamping Force Feedback & Control

Radius Workcell + Injector = Success

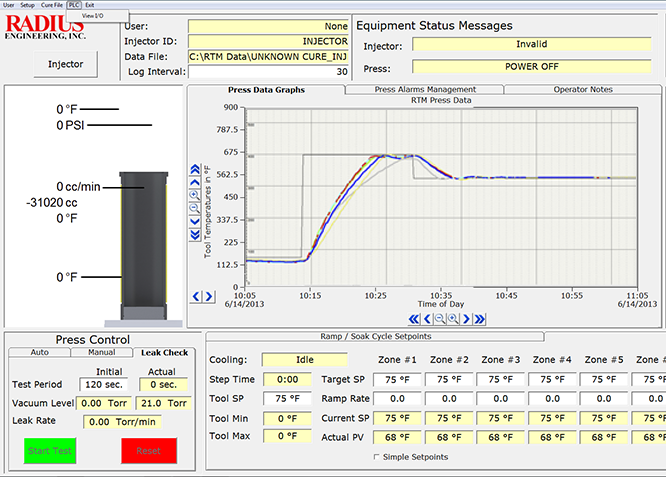

Control System Combines Injection Equipment and Workcell

- Eliminates software and hardware compatibility issues.

- Recipe specific to process guides the equipment operator thru part fabrication.

Single Data Log File

- Process values

- Part and operator identification

- Machine alarms

- System events

- Operator notes

Safety Controls Tie Injection Cycle to Press Status

- Press clamping pressure must be greater than injection pressure.

- Guarding interlocks must indicate all access doors are closed.

The injector connects to the press via one Ethernet cable. One PC controls the entire workcell (press and injector). Custom software tailored to our customer’s specification is used to control the workcell. Because the equipment is networked together, additional safety features are applied in addition to the safety features that our equipment has in their standalone format. One example is that the press will not allow an injection to begin unless the clamping pressure of the press is at least 25 PSI greater than the injector pressure set point. This mitigates the risk of the injector resin pressure opening the tool inside of the press. As a result of one software package controlling the Radius workcell, one data log file is generated after the process is complete. All of the data from the press and injector is in one place that can then be manipulated via Microsoft Excel. This data log file is also completely customizable.

Press Models

- Flat panel press – used by schools & research facilities

- Fixed bolster presses

- Adjustable bolster presses – electric actuators adjust for various tool height

- 130 Ton Press

- 160 Ton Press

- 185 Ton Press

- High Temperature Press

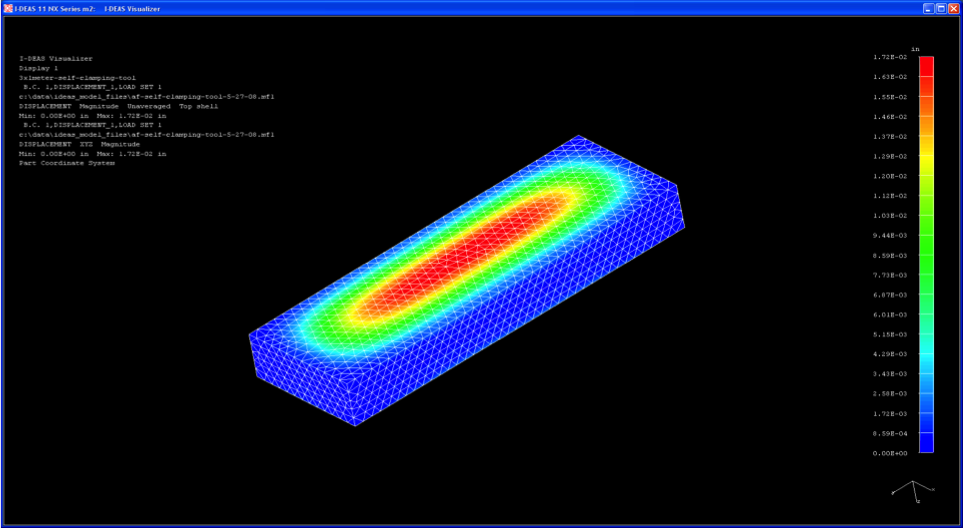

Compare: Press with Bolsters vs. Self Clamping Tool

Radius' Press with Welded Bolsters

- Maintains Surface Tolerances

- Bolsters designed with FEA analysis to maintain less than .125mm tool deflection across the entire surface of the tool.

Competitor's Self-Clamping Tools

- Large tool required to contain pressure = high cost

- Example tool: 1m x 3m x .4m

- Tool wall thickness : 50 mm

- Tool mass: 10,000 kg

- Internal pressure : 150 psi, (10.3 bar)

- 90 M24 bolts required to keep tool closed; even so, bolt stretch = .13 mm

- Maximum deflection of tool = 0.44 mm (far in excess of aerospace tolerances)

- Excess resin injected = approx. 900cc:

- Fiber/resin ratio likely unacceptable

- Costs for rigidity and heating are sunk in every tool

Compare: Radius Pneumatic Press vs. Hydraulic Press

Radius' Pneumatic Press

- Hoses apply pressure evenly across the tool

- Number of inflated hoses can be adjusted to match tool width

- No oil in system

- Eliminates potential contamination

- Pneumatic hoses raise lower bolster

- Creates uniform clamping force on tool

- Allows lower bolster to adjust to tool variations during closure

- Clamping force is evenly distributed

- The number of inflated pneumatic hoses can be optimized for a given tool width

- Clamping force is generated by regular shop air

- Minimum energy use

Competitor's Hydraulic Press

- Hydraulic ram pushes only at center of tool

- Pressure is concentrated in tool center or corners (deformation more likely)

- Oil contaminant

- Potential contamination in molding area

- Requires hydraulic pressure

- 300 Ton press requires up to 5,000 psi

- Upper bolster moves as a single piece

- Can't compensate for misalignment during initial tool closure, which can easily damage tool

- Massive structure required

- Force applied at one or four cylinder locations - massive structure has higher installed cost due to need for special foundations

- More noise

- Higher cost

- Operating cost and life-cycle maintenance are relatively high

Highlighted Projects

Radius Engineering designs and manufactures state of the art resin injection systems that lead the industry in Resin Transfer Molding (RTM) and Same Qualified Resin Transfer Molding (SQRTM). Our injection systems inject single component or pre-mixed multi-component resin systems. Our custom Supervisory Control and Data Acquisition (SCADA) software controls, monitors, and logs critical process parameters including resin pressure, temperature, and flow rate. Custom injection systems are available for your application. Contact Radius Engineering for further information.

Radius Engineering Injection Systems

Features

- Flow Rate Control

- Pressure Control

- Temperature Control

- Up to 600° F (315° C)

- Process Monitoring

- High Vacuum Degassing

- Safety

Advantages

Advantages of purchasing a workcell from Radius Engineering (press and injector)

Increased Process Control

Excellent machine process integration and control when you use a Radius Injector with a Radius press.

SCADA Data Logging

All injection systems and presses include Supervisory Control and Data Acquisition (SCADA) software. The SCADA system designed by Radius Engineering provides control and logging of all injection and press parameters. All equipment communication is controlled via Transmission Control Protocol/Internet Protocol (TCP/IP).

Increased Process Safety

Increased process safety when the injection system is directly connected to the press inhibiting certain functions of the injector until certain critical injection process parameters are satisfied via the press. Contact Radius Engineering for further information.

Radius Injector + Workcell = Success

Control System Combines Injection Equipment and Workcell

- Eliminates software and hardware compatibility issues.

- Recipe specific to process guides the equipment operator thru part fabrication.

Single Data Log File

- Process values

- Part and operator identification

- Machine alarms

- System events

- Operator notes

Safety Controls Tie Injection Cycle to Press Status

- Press clamping pressure must be greater than injection pressure.

- Guarding interlocks must indicate all access doors are closed.

Standard Models

Electric Injector Features

- Color touch screen for system control and monitoring of all injection parameters

- Programmable Logic Controller (PLC) based control of all injection processes

- Precise resin flow rate control provided by a direct current (DC) stepper motor system

- Injection cylinder pressure monitoring and control provided by a cylinder pressure transducer for the duration of the resin injection

- Tool pressure monitoring provided by a tool pressure transducer for the duration of the resin injection

- Resin cylinder heater monitoring and control

- Eight (8) thermocouple inputs included with the injection system for auxiliary temperature monitoring and logging

- Resin transfer injection line heater monitoring and control

- Optional injection cylinder end plug heater monitoring and control

- Optional in-cylinder degassing assembly allows for resin degassing, agitation and resin temperature monitoring directly inside the resin cylinder

- Optional integrated high vacuum system capable of reaching vacuum levels less than 0.01 Torr (0.01 mbar) integrated with the injection system to provide vacuum supply and vacuum monitoring capabilities for RTM processing

- Supervisory Control and Data Acquisition (SCADA) is included with all injection systems with custom Personal Computer (PC) software designed and developed by Radius Engineering. The

- SCADA system provides control and logging of all injection parameters and inputs including pressures, flow rate, vacuum level, temperatures, events, alarms and operator notes. All equipment communication is performed via Transmission Control Protocol/Internet Protocol (TCP/IP).

- See the Accessories page for more information regarding injection system optional equipment

Radius Cartridge System (RCS) Injector

The RCS Injector is a re-useable cartridge based injection system suitable for high-rate Resin Transfer Molding (RTM) and SQRTM production.

Design Features

- Re-useable, self-contained resin container. Ready for injection with piston and end plug pre-installed.

- Fast cartridge change out.

- Resin pressure and flow rate control.

-

Pneumatic actuation provides:

- Resin pressures of up to 250 psi with standard shop air supply.

- Reliable, robust resin displacement system. Used in Radius injection systems for over 20 years.

- Safe pressure control. System automatically retracts piston to relieve over-pressure condition.

- Unique design allows application of vacuum without piston movement.

- Quick & easy cartridge cleaning, re-assembly, and re-fill.

Operating Specifications

| Operating Pressure: | 250 psi | 17.2 bar |

| Operating Temperature: | 250 °F | 121 °C |

| Vacuum Rated: | < 0.5 torr | < 0.6 mbar |

| Volume: | 1950 cc | ~ 2145 g |

| Weight (empty): | 4.5 lb | 2040 g |

| Weight (full): | 9.2 lb | 4185 g |

Custom Injection Systems

Accessories

- In-cylinder degassing end plug (optional) with the following description:

- In-cylinder degassing assembly allows for resin degassing, agitation and resin temperature monitoring directly inside the resin cylinder

- Heated end plug (optional) with the following description:

- The heated end plug is engineered to be used in the SQRTM injection process. The heated end plug provides Proportional-Integral-Derivative (PID) temperature control up to 350*F (180*C). Temperatures are recorded to a log file via the injection system Data Acquisition (DAQ).

- Line heater (included) with the following description:

- Resin transfer injection line heater monitoring and control

- Injection vacuum system (optional) with the following description

- Optional integrated high vacuum system capable of reaching vacuum levels less than 0.01 Torr (0.01 mbar) integrated with the injection system to provide a vacuum supply and monitoring capabilities for RTM processing

- Tool pressure transducer (included) with the following description

- Tool pressure monitoring provided by a tool pressure transducer for the duration of the resin injection

- Visit the Radius Engineering online store for more information. https://shop.radiuseng.com/

Project Portfolio

Featured customer projects using Radius Engineering injection equipment.